Revolutionizing Temperature Monitoring: HANI Sensor by Omega Takes Center Stage in Food and Beverage Manufacturing

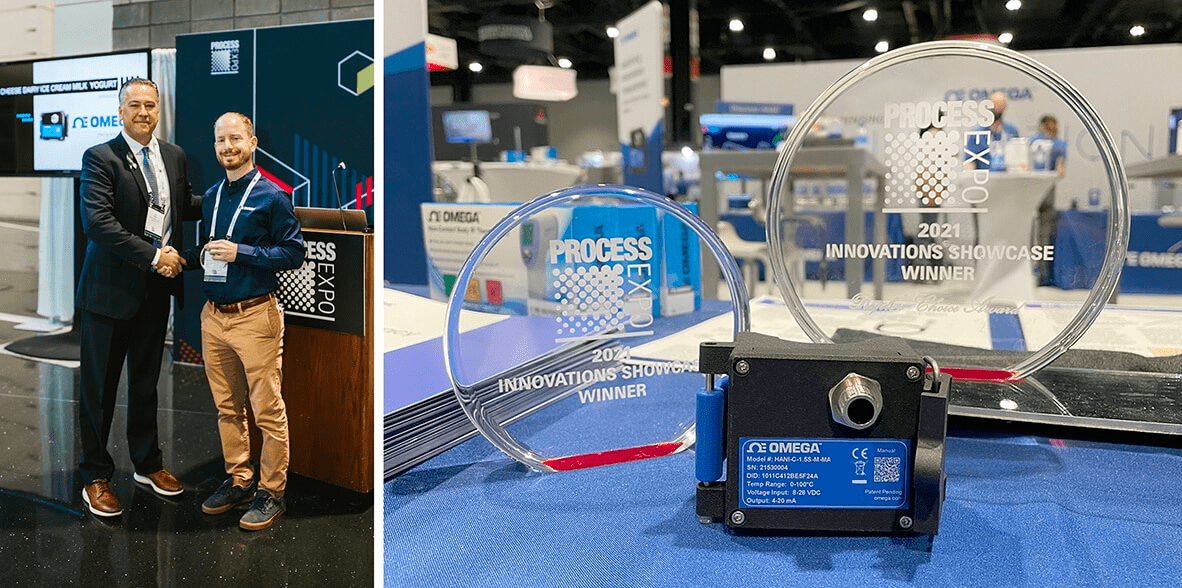

In the ever-evolving landscape of Food and Beverage manufacturing, Omega’s groundbreaking HANI temperature sensor emerges as a game-changer. Awarded top honors at the 2021 Process Expo, the HANI sensor not only clinched victory in the Innovations Showcase but also secured the coveted People’s Choice award in the Cheese, Dairy, Ice Cream, Milk, and Yogurt category.

Unveiling the Unassuming Hero

In the bustling atmosphere of the 2021 Process Expo, Omega Engineering celebrated a triumph that echoed far beyond the event. The HANI temperature sensor, a seemingly unassuming device, managed to capture the attention of industry professionals and media alike, swiftly becoming the talk of the town. The HANI sensor’s success wasn’t just limited to accolades; it resonated with the audience, leading to on-the-spot purchases at the expo.

The Problem at Hand: Probes and Pipes

To comprehend the significance of the HANI sensor, it’s essential to recognize the challenges faced by Food and Beverage manufacturing professionals. Traditional temperature readings involved invasive probes inserted into the process line, necessitating disruptive activities like cutting, drilling, and sanitary welds. This not only incurred significant costs but also posed the risk of cross-contamination and hindered production efficiency.

HANI: High Accuracy, Non-Invasive

The HANI sensor introduces a paradigm shift by offering high-precision temperature measurements of moving process media inside a pipe without the need for invasive probes. Unlike traditional sensors, the HANI sensor attaches to the external surface of a pipe, eliminating the need for costly and time-consuming installation processes. It ensures accuracy without touching the product, mitigating the risk of contamination and blockages.

Testimonials Speak Volumes

Industry professionals have lauded the HANI sensor for its revolutionary approach. Eric Anderson, Chief Brewing Officer & Co-Founder at Saucy Brew Works, expressed, “Until the HANI was made available, I had no way to non-invasively measure temperature in a pipe accurately.”

Seamless Installation, Unparalleled Accuracy

From unboxing to measurement-ready, HANI sensors take approximately 10 seconds to install. The strap is wrapped around the pipe, the quick-latch mechanism is engaged, and the sensor is ready to deliver immersion-probe level temperature measurements. Electrical connections can be established via analog systems, USB cables, or wirelessly.

Cutting-Edge Technology: Thin-Film Heat-Flux Sensor

The HANI sensor stands out as the only temperature sensor on the market employing a thin-film heat-flux sensor. Combined with Omega’s proprietary algorithm, it achieves accuracy (±0.9◦F) and response times (t63 = 5 sec) comparable to immersion RTD temperature sensors, distinguishing it as the sole non-invasive sensor capable of such precision.

People’s Choice: A Testament to Impact

Winning the People’s Choice award at the Process Expo underscores the HANI sensor’s significant impact on the Food and Beverage industry. It has transcended industry norms, addressing long-standing challenges that were once considered unavoidable.

Embracing the Future

From awards to widespread acclaim and seamless integration into diverse processing systems, the HANI sensor has proven its mettle as a revolutionary technology for the Food and Beverage industry. Omega, through ProcessPneumatics.com, proudly brings this innovative solution to the forefront, ushering in a new era of temperature monitoring in manufacturing and processing.

For inquiries about incorporating the HANI sensor into your processes, please contact ProcessPneumatics.com today.