How to Simplify Hygiene Compliance with Magnetic Flow Meters in CIP Systems

Introduction

In industries like food and beverage, keeping equipment clean is crucial for safety and efficiency. Clean-in-place (CIP) systems are the go-to for this job, using mechanical, thermal, or chemical methods to clean equipment without disassembly. Monitoring the flow, temperature, and concentration of cleaning agents is key for meeting hygiene standards. Traditionally, this required multiple sensors, but now, a single magnetic flow meter can handle all three measurements, simplifying monitoring and cutting costs.

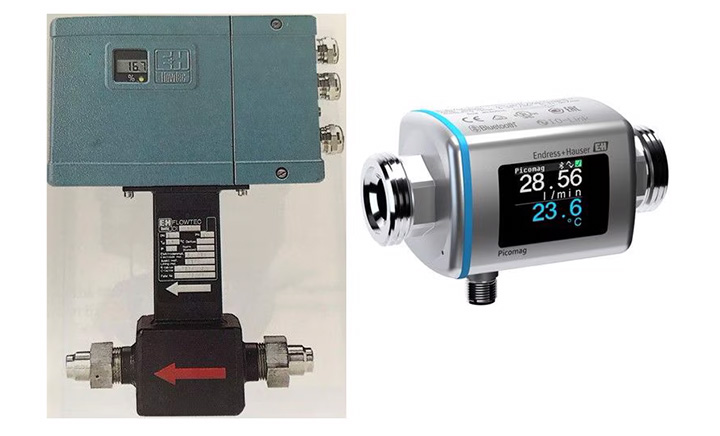

The Solution: Picomag Magnetic Flow Meter

The Picomag Magnetic Flow Meter is a game-changer. It’s compact, cost-effective, and measures temperature, flow, and conductivity all in one go. Plus, it’s user-friendly, with Bluetooth connectivity and integration options, making it a breeze to set up and use. Its durable design means it can handle tough conditions without losing accuracy.

Installation Made Easy

Installing the Picomag is a cinch. Just find a straight section of pipe, connect the meter, configure the settings, and you’re good to go. Its small size means it can fit into tight spaces, and it doesn’t need any special inlet or outlet runs.

Benefits and Beyond

With the Picomag, you can ensure your cleaning cycles are thorough and efficient, all while saving time and money. Plus, its remote operation capability means you can keep an eye on things from anywhere, even in harsh environments. And with its integration options, you can take your CIP system to the next level, automating processes for maximum efficiency.

Conclusion

In the world of hygiene compliance, simplicity is key. With the Picomag Magnetic Flow Meter, meeting CIP system requirements has never been easier. Say goodbye to complicated setups and hello to streamlined monitoring and improved efficiency. Contact our friendly Product Specialist to discover how Picomag Magnetic Flow Meter can transform your cleaning process!