How to Measure an Industrial Coffee Grinder Motor’s Temperature During Grinding

Introduction

Monitoring the temperature of a motor in an industrial coffee grinder is crucial for understanding the strain on the motor during the grinding process. Excessive strain can lead to overheating, reduced efficiency, and potential damage to the motor, resulting in costly repairs and downtime. By closely monitoring the temperature, operators can ensure the motor operates within safe limits, optimising performance and extending the equipment’s lifespan. Additionally, understanding the motor’s thermal behaviour during grinding helps identify potential issues early, allowing for preventive maintenance and ensuring consistent product quality.

Required Products

- OMEGA 5SC-TT-K-30-36 Thermocouples: These are ready-made, insulated thermocouples with Kapton®, PFA, glass braid insulation, and molded connectors. They’re durable, economical, and can measure temperatures up to 500°F (260°C), making them ideal for the food industry.

- OMEGA HH378 Data Logger: This device features a high-resolution, fast analog-to-digital converter. It can store data internally or save it directly to a computer via a PC interface. The included software enables you to export the data to Excel or other data analysis tools.

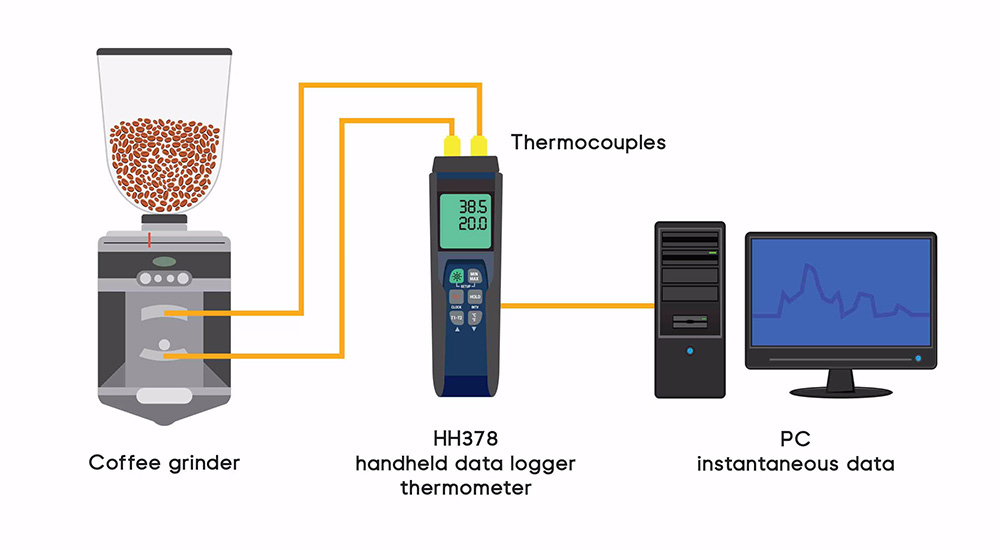

Setup and Operation

- Mount the Thermocouples: Attach the thermocouples to various areas of the motor to get a comprehensive temperature reading.

- Connect to the Data Logger: Attach the thermocouple wires to the data logger.

- Real-Time Monitoring: The thermocouples will measure the motor’s temperature continuously and send this data to the data logger, which displays it in real-time.

- Data Download and Analysis: Connect the data logger to a PC via USB, download the data, and use the provided software to visualise and analyse the temperature readings.

Results

By using this setup, you can monitor the motor’s temperature in real-time and easily download and visualise the data. This helps you understand the strain on the motor during the coffee grinding process, indicated by temperature variations.

Pro Tip

Motors can generate significant electrical noise, which may interfere with the thermocouple readings, especially when using multiple channels. To minimise interference:

- Use Filters: Implement a simple filter for each channel to reduce AC line noise.

- Shorten Leads: Long leads can act as antennas, picking up unwanted electrical and magnetic interference.

- Opt for Insulated Thermocouples: Insulated thermocouples help shield against electrical interference.

Summary for Coffee Makers

Investing in a temperature monitoring system for your industrial coffee grinder is essential for ensuring the longevity and efficiency of your equipment. By tracking the motor’s temperature in real time, you can prevent overheating, reduce the risk of costly repairs, and minimise downtime. This proactive approach not only protects your investment but also ensures consistent grinding quality, which is crucial for maintaining the flavour and aroma of your coffee. With the ability to monitor and analyse temperature data, you can optimise the performance of your grinder, enhance operational efficiency, and deliver a consistently high-quality product to your customers.