14 Surprising Ways Machine Vision is Making a Difference

Ever wondered how your favourite foods stay consistently delicious or why some products look flawless every time? Behind the scenes, machine vision technology plays a key role in ensuring quality and consistency. Let’s dive into some unique, real-world uses of this technology—many of which might surprise you!

How Machine Vision is Transforming the Food Industry

Maintaining high standards in food production isn’t just about taste; it’s also about safety, freshness, and compliance with regulations. Here’s how machine vision is quietly helping the food and beverage industry stay on top of things.

- Inspecting Chicken and Turkey

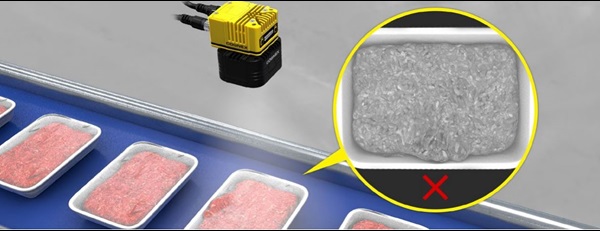

Cameras check for missing wings or legs, bruises, and discolouration in poultry. This ensures every piece meets both visual and safety standards before it reaches consumers. - Sizing Meat for Consistent Cooking

Machine vision ensures each cut of meat is perfectly sized for even cooking. This guarantees products are cooked consistently before packaging. - Checking Package Seals and Labels

Vision systems ensure that absorbent pads, seals, and labels are correctly applied on meat products, keeping everything fresh and properly marked. - Sorting Meat Cuts

These systems can identify and classify different cuts of meat at high speed, ensuring beef or poultry is sorted correctly without delays.

Unexpected Uses in Other Food Applications

- Pizza Box Tracking

Machine vision helps manage inventory by identifying and tracking pizza boxes, ensuring restaurants are always ready to package their pizzas. - “Donut Check” for Presentation

Cameras verify that doughnuts are aligned correctly in their boxes, improving both presentation and product appeal. After all, they should look as good as they taste!

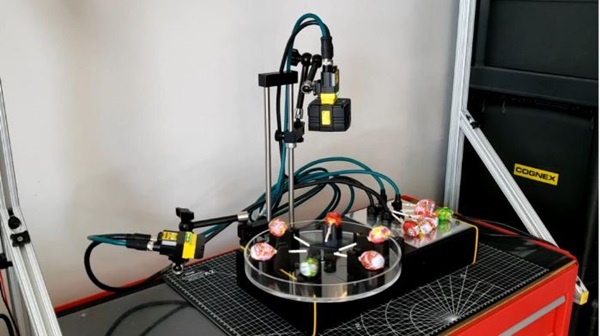

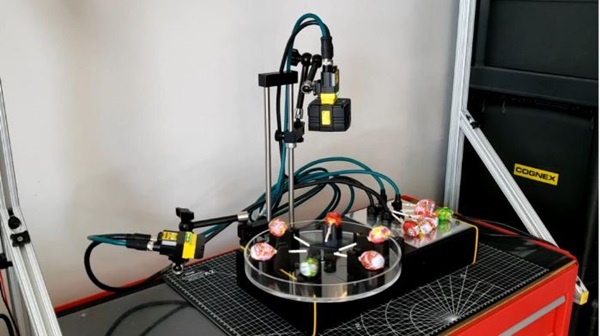

- Lollipop Sorting with AI

Using edge learning AI, the system sorts lollipops by colour, shape, and quality—making sure only perfect treats get packaged. - Inspecting Chocolate Molds

Sensors check for defects in chocolate moulds to ensure smooth, flawless candy every time. - Coffee Ball Inspection

Vision technology scans coffee balls for cracks or defects, ensuring manufacturers maintain high production standards.

Machine Vision Beyond Food: Other Surprising Uses

- Dog Tag Identification for the Military

One system accurately reads detailed data on dog tags, ensuring important information is correctly recorded for military personnel. - Wheel Inspection in the Automotive Industry

Cameras read markings and IDs on car wheels, helping manufacturers meet safety standards before shipping.

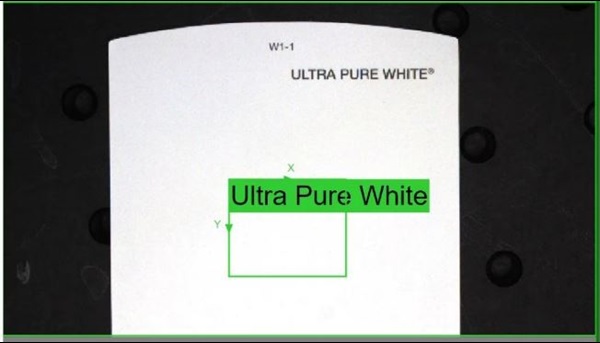

- Colour Shade Detection

Vision systems can identify and sort subtle colour variations, ensuring products match the right shades on production lines. - Detecting Foreign Objects on Production Lines

These systems identify unwanted objects—like leaves sneaking into a product line—and remove them to maintain product quality. - Finding Waldo with Facial Recognition

Yes, it’s true! Machine vision can find Waldo instantly using advanced facial recognition software. While this might take the fun out of the game, it shows how far this technology has come!

Innovations That Keep Evolving

As you can see, machine vision technology isn’t just limited to one type of application—it’s being used creatively across multiple industries. With tools like smart cameras and AI-powered systems, manufacturers can automate processes, improve quality, and reduce waste.

The future of machine vision is bright, with even more out-of-the-box solutions just waiting to be discovered. Whether it’s improving food packaging or making manufacturing lines more efficient, this technology is already changing the way we work—and it’s just getting started!

Machine vision may be working quietly behind the scenes, but its impact is undeniable. From perfect doughnuts to military dog tags, it’s clear this technology is transforming industries in ways we never imagined. Want to learn how Machine Vision or Cognex products can improve your process? Talk to our Product Specialist today!